Small Size Multi-Port Extruded Aluminum Micro Channel Tube

Aluminum Tubing & Piping What is Aluminum Tubing & Piping? Aluminum piping and tubing is silvery-white, soft, and ductil

Send your inquiryDESCRIPTION

Basic Info

| Transport Package | Carton |

| Specification | Customized |

| Trademark | ALUT |

| Origin | Guangdong, China |

| HS Code | 76042990 |

Product Description

Aluminum Tubing & Piping

What is Aluminum Tubing & Piping?

Aluminum piping and tubing is silvery-white, soft, and ductile. The metal belongs to the boron group. Aluminum is the third most abundant element present on earth. Aluminum has low density. When exposed to corroding environments, aluminum forms a passivating coating on its surface, which helps it avoid further corrosion on its internal structure. Aluminum is mostly made into an alloy by elements like copper, manganese, zinc, magnesium, and silicon.

These pipes and tubing only have 30% of coppers' density, yet have good electrical and thermal conductivity. Aluminum can be categorized as a superconductor, since it is capable of conducting at cold temperatures.

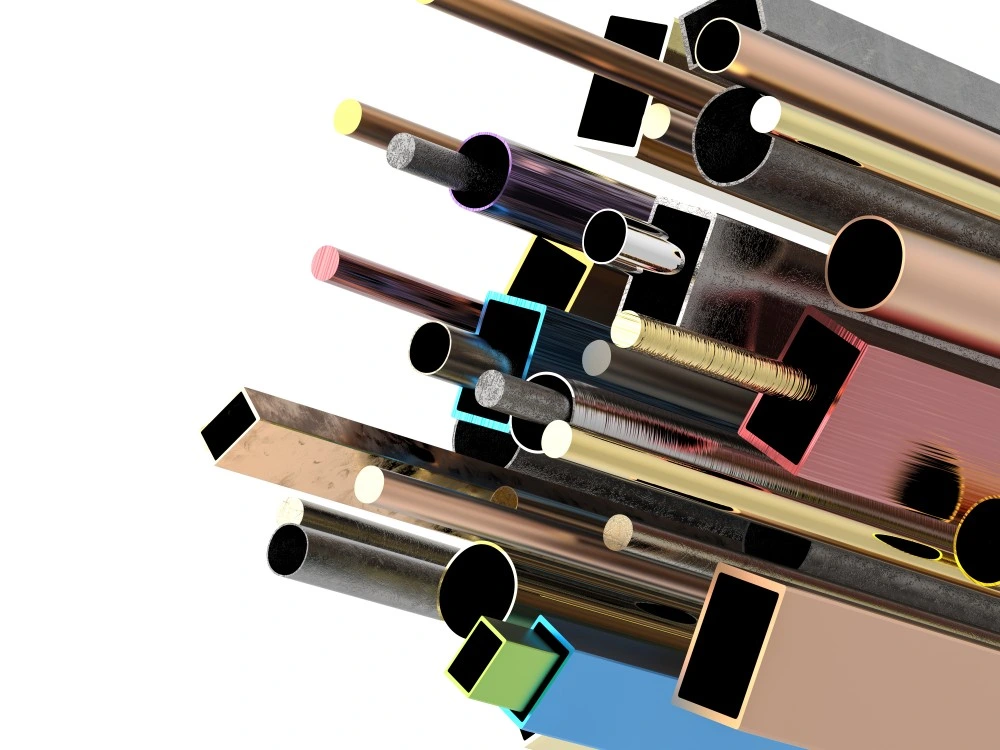

Piping is a circular tube for the flow of gasses and fluids, characterized by a small pipe size offering a vague representation of the piping conveyance capacity. Tubing is a circular, oval, rectangular, or square hollow segment characterized by outer diameter and wall thickness, denoted in millimeters or inches.

The choices may be overwhelming when choosing a tube type; both aluminum and stainless steel are available in a number of alloys and tempers, all with their own mechanical and physical properties.

Strength of Aluminum Tubing & Piping vs. Steel Tubing & Piping

The strength of every material may be defined by a physical factor called Young's modulus of elasticity, determined in force per unit area. This factor can be utilized to evaluate the strength of aluminum and steel tubing.

Young's Modulus - At 70 °F, Young's modulus of elasticity for aluminum is 10 million psi. For steel, irrespective of the type, it's about 30 million psi. This effectively implies that steel tubing is 3 times stronger than aluminum tubing for the same dimensions.

Material Weight - Size for size, steel is about three times heavier than aluminum. The walls of aluminum tubing are required to be three times thicker than the walls of steel tubing so the weight advantage is insubstantial.

Diameter - The strength of aluminum or steel tubing also depends on the tubing's diameter. The nominal diameter of the tube, the more intrinsic the strength and vice versa.

Manufacturing of Aluminum Tubing & PipingAluminum Extrusion

Aluminum extrusion is a procedure where the aluminum alloy metal is forced through a die of a specific cross-sectional area.

Aluminum extrusion can be compared to the squeezing of toothpaste from a tube. A powerful ram forces the aluminum through a die, which comes from the die's opening. It emerges in a shape same as that of the die and is pulled over a run out table. At an elementary level, the procedure of aluminum extrusion is fairly simple to understand.

The force applied can be compared to the force applied while squeezing a toothpaste out of a tube with one's fingers. As the tube is squeezed, the toothpaste comes out, taking the shape of the opening of the tube. The toothpaste tube's opening basically serves the same purpose as an extrusion die. Because the opening is a solid round, toothpaste emerges as a solid, long extrusion.

Heat Treating: Improving Mechanical Qualities

Alloys in the 7000, 6000, and 2000 series could be heat treated to improve their final yield stress and tensile strength.

To attain these improvements, piping is put into aging ovens where their aging procedure is sped up, and brought to T6 or T5 tempers.

How do their qualities change? Untreated (T4) 6061 aluminum has tensile strength of 241MPa/35000psi. Heat treated (T6) 6061 aluminum has tensile strength of 310MPa/45000psi.

After heat treatment, piping is finished.

Surface Finishing: Improving Appearance and Corrosion Resistance

Aluminum piping can undergo several finishing operations. The two major reasons to choose a finishing method is they improve the appearance of the aluminum and improve its corrosion properties.

For instance, the operation of anodization thickens the material's naturally occurring oxide coating, enhancing its resistance to corrosion and also making the material more wear resistant, enhancing surface emissivity, and offering a porous surface which can accept different colored dyes.Other finishing procedures like powder coating, sandblasting, painting, and sublimation (to make a wood look), can be done as well. There are many fabrication choices for extrusions.

Differences between Drawn vs. Extruded Aluminum

Drawn Aluminum Process

The drawn aluminum tubing process happens by having the aluminum pulled, or drawn into the die cavity, during which the aluminum undergoes what is called plastic deformation. Plastic deformation happens when the aluminum is stretched to achieve the desired shape. When stretching aluminum, it's important to pay close attention to the flexibility and elasticity of the metal. Stretch too much and it will become weak and brittle. Drawn aluminum is most often used to create products including pots, cans, tubes and other circular objects.

Extruded Aluminum Process

Extruded aluminum differs from drawn aluminum in that the formed shape is made by first heating the metal to a very high temperature until it is soft and malleable but not liquid. After the aluminum has been heated, it is then forced or pushed through a die. The extruded metal tubing product that comes out the other end will be molded by the die and shaped to the desired final product. To visualize the extrusion process, it can help to picture a tube of toothpaste. In this case, the toothpaste is shaped by the circular opening through which the toothpaste is pushed. After the aluminum has been extruded, it will begin to cool and harden. As it hardens, the finished extruded tubing product becomes strong and durable and will hold the desired shape.

Differences

While both processes can be used to create similar finished products, there are a few differences found between the two. These differences include:Product accuracy. Cold drawn aluminium tubes can be controlled to an accuracy of 0.02mm and are commonly used for telescopic tubes as well as precision instruments.

Cost. In general, the extrusion process tends to be cheaper than the drawn aluminum tubing process. This is because cold drawing aluminum often requires a larger collection of tools and materials to complete.

Products created. The extrusion and drawing processes will often be used to produce different types of products. For example, extruded aluminum can be used to make tubing, doors, window frames, brackets, and railings. Drawn aluminum will similarly be used to create tubing, in addition to products like cans and pots.

Shape of Aluminum Tubing & Piping

Metal tubing is highly rigid. This enables them to remain in shape. Most tubing utilized for smooth liquid flow comes with round cross-sections. However, there are also metal tubing with various shapes, like rectangular, oval, square, and circular. Some manufacturers also offer customized shapes. But they are more costly than regular metal tubing. Circular tubing is the most popular shape among these, as it provides constant distribution throughout the tubing.

Heat sink aluminium tubes, generally this type of tube is used in the lighting and optoelectronic industries to add heat sink fins to the inside and outside of the aluminium tube.

Types of Aluminum Tubing & Piping

5052 Aluminum Pipes

5052 aluminum pipe is a variation of aluminum alloys that is improvised for improved performance. The 5052-0 aluminum pipe is an aluminum and magnesium alloy which is modified for corrosion resistance. It is an average strength magnesium alloy. The composition has iron, silicon, manganese, copper, and other elements in small quantities.

The 5052 aluminum seamless pipe is produced directly from solid metal so that there's no welding and the piping is dimensionally precise.

The aluminum 5052 box pipe is utilized in applications that need high strength and require staying in shape for a longer time. The aluminum alloys have longer lifespans or long-lasting life. The strength of the piping differs with each application, the form, and shape of the aluminum pipe used.

The 5052-0 aluminum welded piping is welded from aluminum sheets. This enhances the strength more than the ordinary piping. However, the aluminum 5052-0 ERW pipe can only be cold worked to strengthen it more after production. Heat treating is not appropriate for any kind of aluminum alloy.

The 5052 aluminum alloy hollow pipes are some of the most utilized pipes since it is the aluminum alloy 5052 round pipe. There are more like the square pipe, box pipe, hexagonal and rectangular, and hydraulic types. The most utilized is the round one. The 5052-0 aluminum alloy square pipes are frequently utilized with structural applications.

6061 Aluminum Pipes

6061 aluminum pipe is a variant of aluminum pipe grades. Pure aluminum and alloyed aluminum is utilized for making the aluminum pipes as well. The 6061 pipes are made from a silicon and manganese alloy of aluminum. There are various schedules of the piping which indicate the pressure classes and the wall thickness. The 6061 T6 schedule 80 aluminum piping is an average pressure grade, and it can withstand substantial pressure in a domestic application.

The aluminum 6061-T6 piping is an average to high strength metal which has a good durability paralleled to other grades. The 6061-T6 aluminum structural piping is utilized in structural applications which need high strength. Aluminum is weak, but the alloying and the heat treating make it average to high strength, which could then be utilized in applications.

The 6061 aluminum thin walled pipe is utilized in applications in which the finish must be good-looking. Almost all aluminum alloy piping metals have a good finish and look better. Aluminum piping is also utilized in aesthetic applications. However, aluminum reacts with water. So it isn't ideal as a plumbing metal under normal conditions.

The 6061-T6 aluminum seamless piping is modified for strength, yet it maintains most of the good mechanical characteristics of aluminum, like corrosion resistance. Most applications of the 6061 T651 aluminum welded piping can be seen in the aerospace and aircraft industries where weight must be reduced. The aluminum alloy 6061 ERW piping is easy to weld, so applications in which welding is needed can use these pipes.

6063 Aluminum Pipe

6063-T6 aluminum pipes are silicon magnesium alloys of aluminum. These are used to improve the strength and corrosion resistance properties of aluminum. This type of metal can be heat treated after extrusion to enhance the strength and be toughened. The 6063-T5 aluminum pipes have good elongation of 8% and good tensile strength. There are different classes and schedules to determine different mechanical characteristics of the material.

6063 aluminum pipes are drawn from the raw metal and so have a good finish. The fine grain arrangement of the metal also makes fine anodizing possible. Aluminum 6063 welded pipes are stronger and can also be welded. The utilization of t6, t5, t4 types of the metal are seen in many industries. The 6063 types are welded using tungsten inert gas welding.

6063 is utilized in architectural constructions which are visible as they offer aesthetic appeal. The 6063-T6 aluminum hollow pipe is one of the most utilized kinds of pipe though there are other types and shapes.

Aluminum 6063-T6 round pipes are the most utilized shape, but there are other shapes like the 6063-T5 aluminum rectangular pipes, hexagonal pipes, square pipes, etc. The use of this grade includes applications in window frames, door frames, roofs, and sign frames. These are relatively medium strength.

7075 Aluminum Pipes

7075 Aluminum Piping is called an aircraft grade aluminum alloy pipe. The alloy contains zinc and is extremely stronger. AL alloy 7075 piping is among the many aluminum alloys which are utilized in various industries and applications.

The 7075 aluminum seamless pipes are drawn from the raw metal, and it enables the piping to be precise in sizes. Since the many applications of the 7075 metal is in the aircraft industries, the piping has to have precise dimensions. The aluminum 7075 box pipes are used in applications where strength is much prioritized. They are utilized in hydraulic systems for lifting tasks.

The 7075 aluminum alloy hollow pipe is one of the commonly utilized types. Due to strength needs, the 7075 alloy square tubes are also commonly utilized in the aerospace industry.

Benefits of Aluminum Tubing & Piping

The benefits of aluminum tubing and piping include:

- Flexibility - Combination of aluminum's characteristics mean it can be simply shaped by any of the major industrial metalworking processes.

- Lightweight - This makes it cheaper and simpler to transport and manage on site.

- Strength - The usage of aluminum in construction helps architects meet performance requirements while reducing expenditure on foundations. Alloyed aluminum can be a third of the weight of steel, but as strong as steel.

- Durability - Building items made from its alloys are weatherproof, corrosion resistant, and resistant to UV rays guaranteeing optimal performance on a very long lifespan.

- Corrosive Resistance - Natural oxide layer offers an effective protective barrier from elements which wear other metals.

- Insular - A coating of insulated aluminum cladding could be four times more effective than uninsulated timber cladding.

- Recyclability - 100% recyclable and utilizes only 5% of the energy utilized to produce the original product. Almost all aluminum utilized in construction has been recycled.

Drawbacks of Aluminum Tubing & Piping

Aluminum tubing doesn't have a great strength to weight ratio. Certain alloys of aluminum tube don't have the same corrosion resistance level like stainless steel. That's why aluminum tubes aren't a prevalent option for electrical cables.

Aluminum tubes need special procedures to be welded. Welding wears off from tooling, or more precisely, the aluminum tube oxide layer which forms upon it. It is more costly than steel.The first factor to consider when buying aluminum tubing is what industry it is to be used and what qualities are required in this industry. Light weight, durability, strong plasticity, low maintenance cost, high toughness, and corrosion resistance are features of aluminum tubing.

Related Products

-

![1060 Ho Capillary Aluminum Tube for Electric Baking Pan, Refrigerator]()

1060 Ho Capillary Aluminum Tube for Electric Baking Pan, Refrigerator

-

![1050 1060 Lwc Aluminum Capillary Tube for Refrigeration]()

1050 1060 Lwc Aluminum Capillary Tube for Refrigeration

-

![Aluminum Capillary Tube/ Pipe Price 8mm Small Diameter]()

Aluminum Capillary Tube/ Pipe Price 8mm Small Diameter

-

![Sublimation Aluminum Sheet 1050 1060 5754 3003 5005 5052 5083 6061 6063 7075 H26 T6 Aluminum Sheet Strip Coil Plate Foil Roll]()

Sublimation Aluminum Sheet 1050 1060 5754 3003 5005 5052 5083 6061 6063 7075 H26 T6 Aluminum Sheet Strip Coil Plate Foil Roll